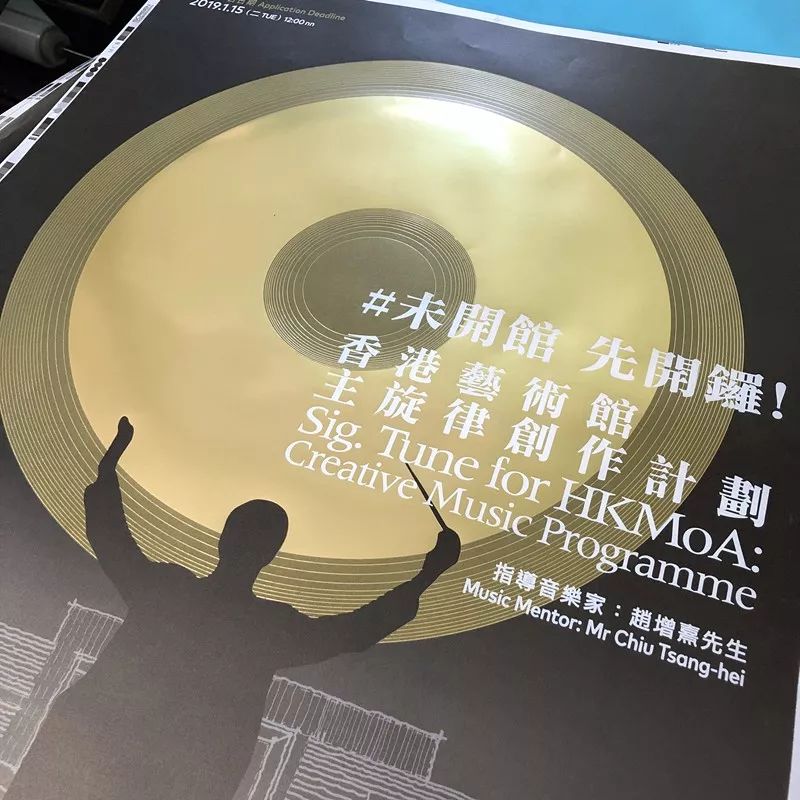

Stamping ne mai muhimmanci karfe tasiri surface ado hanya. Ko da yake zinariya da azurfa tawada bugu yana da irin karfe luster ado sakamako dazafi stamping, har yanzu yana da mahimmanci don cimma tasirin gani mai ƙarfi ta hanyarzafi stamping tsari.

Ci gaba da bidi'a nayin hatimi kayan aiki da kayan tallafi sun wadatar da sifofin maganayin hatimi dabaru. Yanzu akwai nau'ikan guda bakwaiyin hatimi dabaru:

01: Tambayoyi na yau da kullun

Mafi na kowazafi stamping shine a bar komai a kusa don haskakawazafi stamping jiki. Idan aka kwatanta da sauran zafi stamping, samar da tsari ne in mun gwada da sauki. Idan adadin bai girma ba, ana iya amfani da farantin zinc don yin tambarin zafi.Flatyin hatimi yana nufin cewa datum jirgin ne lebur mutu, wanda aka hatimi a kan wani lebur aiki yanki ko wani ɓangare na aikin yanki.

Irin wannan ra'ayi na iya zama zane-zane da rubutu, wanda zai iya zama zafi mai zafi a kan jirgin sama; Hakanan yana iya zama farantin silicone mai lebur, wanda yake zafi hatimi akan hoton da aka ɗaga da rubutu.

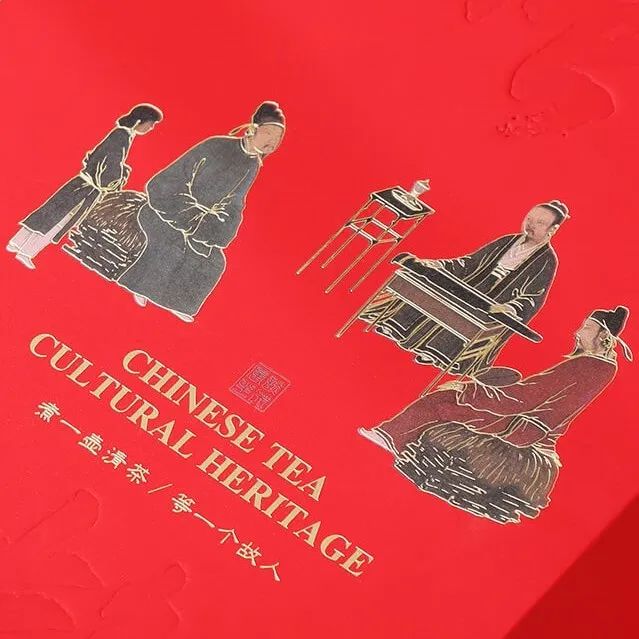

02: Filin anti-farar hatimi

Sabanin falonyin hatimi Hanyar, an bar sashin jigon babu komai, yayin da bangaren baya yakezafi stamping. Girman girmanzafi stamping yanki ya dogara da buƙatun ƙirar samfur. Idan dazafi stamping yanki yana da girma, wajibi ne a yi la'akari da ko aikin adhesion ya dace da bukatun tsari.

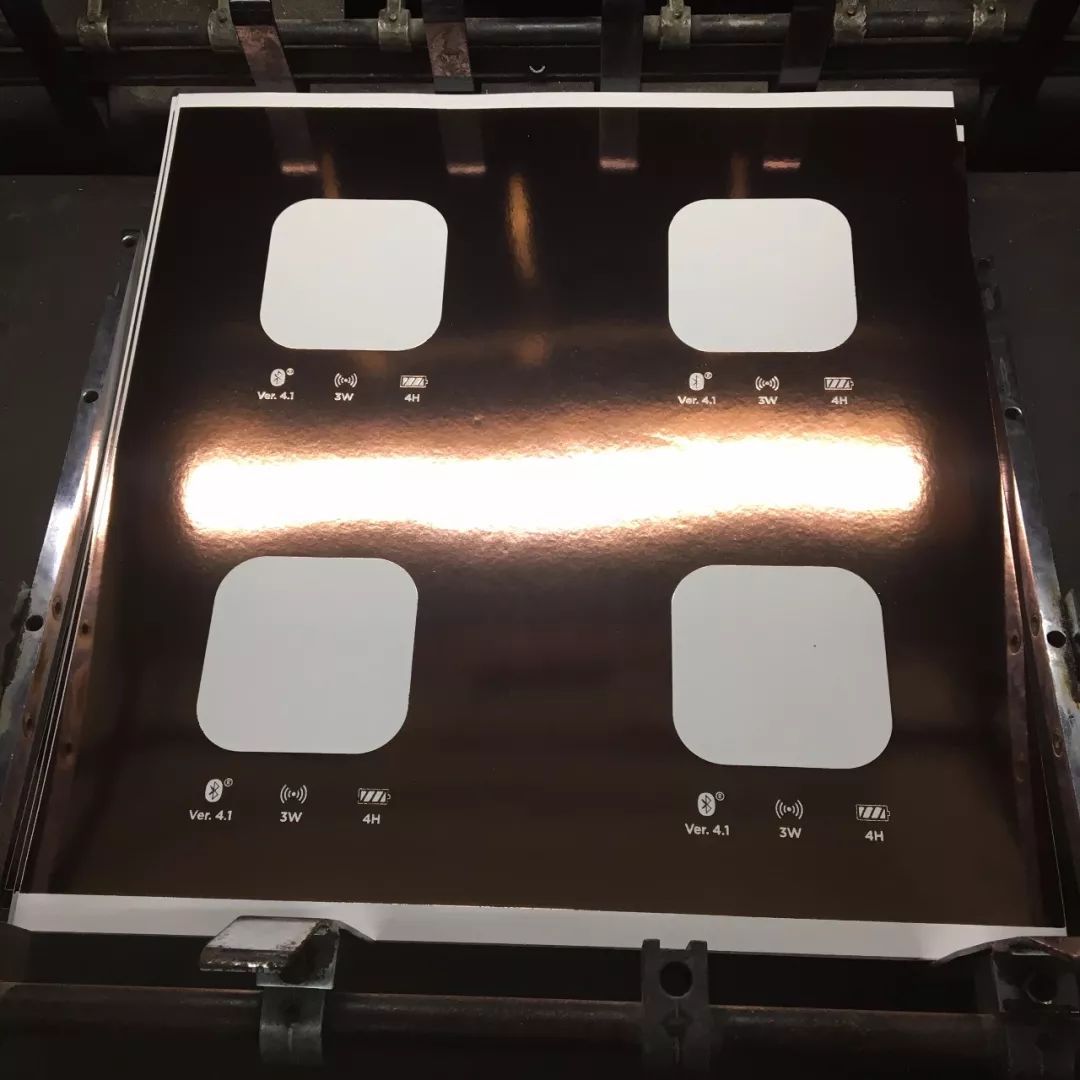

03: Saita tambari

Dangane da buƙatun zane-zane, don yin hatimi da bugu na ɓangaren haɗe-haɗe, bugu a cikin tambarin farko. A cikin tsari na samarwa, alignment yana da girma, kuma daidaitawa daidai ne don samun sakamako mai kyau.

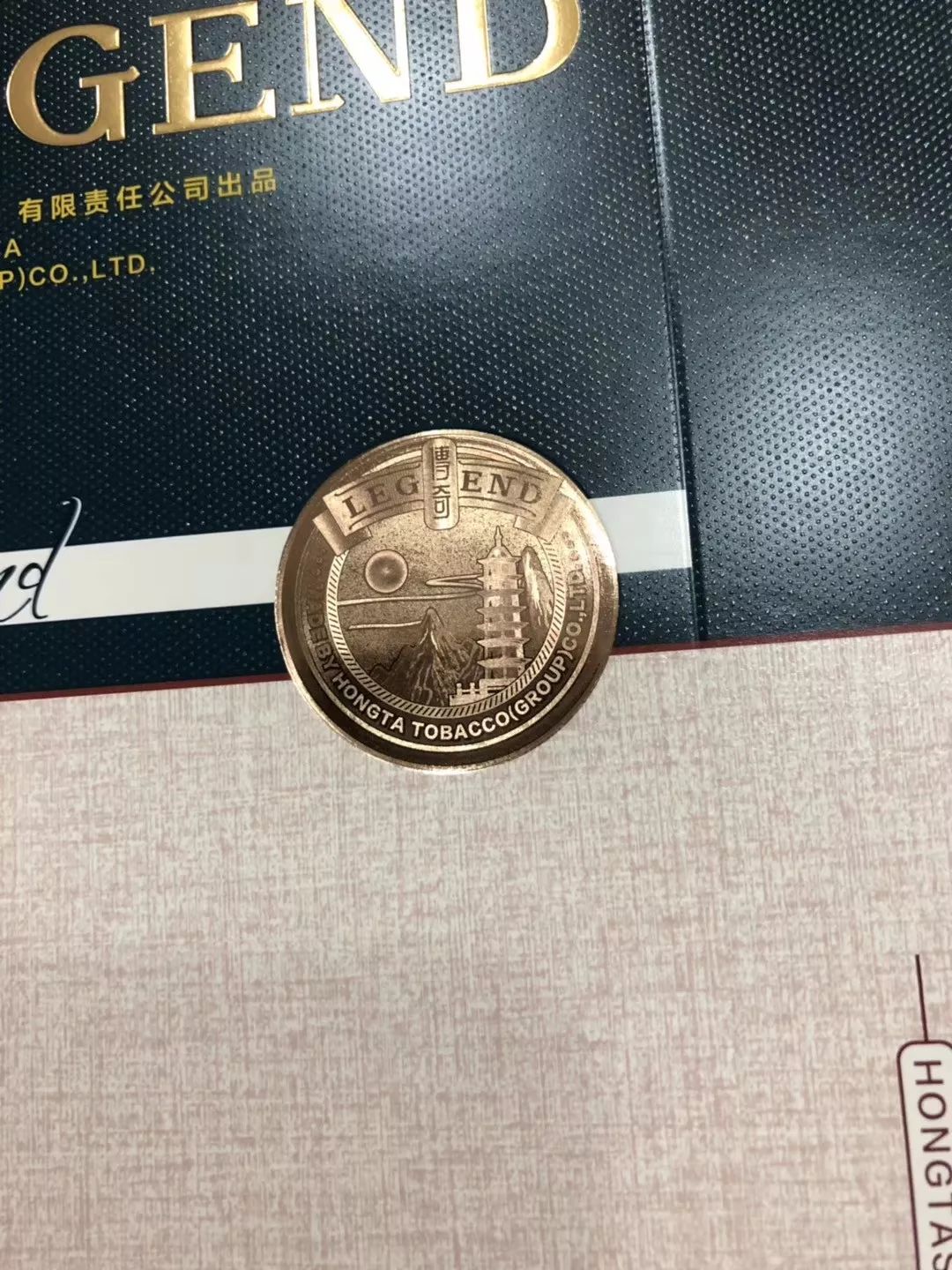

04: Tambarin hatimi

A lokacin samar dayin hatimi farantin, babban hoton da bayanan baya an raba su ta hanyar layi na kauri daban-daban ko shugabanci don samar da tasirin refraction da kuma jaddada ma'anar fasaha na layin zane. Gabaɗaya, ana amfani da farantin zanen laser.

05: Tambayoyi da yawa

Maimaituwazafi stamping fiye da sau biyu a cikin wannan yanki mai hoto yana buƙatar sarrafa tsari da yawa. A lokaci guda, dole ne a biya hankali ga daidaituwar nau'ikan nau'ikan zinare guda biyu don hana abin da ke faruwa na mannewa mara kyau.

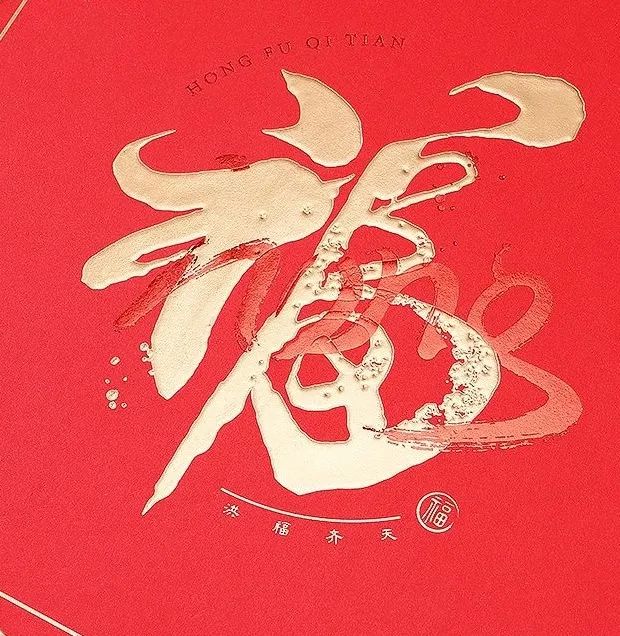

06: Tambarin da aka sanya

Daidai ne da ƙaddamarwa da ƙaddamarwa, amma ƙaddamarwa da ƙaddamarwa sun fi mayar da hankali ga ingancin ƙaddamarwa maimakon tasiri. Yawancin lokaci, ana amfani da faranti da kayan kwalliya, kuma tsayin daka ya kamata ya kasance cikin kewayon tashin hankali na bangon zinariya.

Abubuwan da aka sarrafa ta hanyar embossingyin hatimi fasahar gabatar embossed uku-girma juna sakamako, don haka da aiwatar da bugu kafinyin hatimi an karbe shi. A lokaci guda, saboda girman daidaito da buƙatun inganci, ya fi dacewa don amfanizafifasahar hatimi.

Kamar yadda zaku iya tunanin, masu zanen kaya ya kamata suyi la'akari da rubutu, nauyi, jakar zinariya dabugutawada lokacin zabar takarda ko wasu kayan jigilar kaya don tsarin hatimi mai girma uku. Daidaita sassan gaba da baya yana da mahimmanci.

A lokaci guda, kauri na takarda zai iyakance inganci da tasirin abin da aka gama yayin aiki. Misali, takarda da tayi sirara sosai ko kuma bata da tauri zata haifar da fashewar takarda.

07: Tasirin rubutu na musamman

Bisa ga bukatun kerawa, samfurin tasiri na musammanyin hatimi an yi shi don haskaka tasirin inji na musamman daban-daban.

A aikace aikace nazafi stamping tsari, zaɓin ƙarfeyin hatimi farantin karfe,zafi stamping takarda, takarda dayin hatimi magana kai tsaye yana shafar karsheyin hatimi tasiri.

Yanzu ana amfani da tambari sosai a wurare daban-daban na bugu da tattara kaya. Har ila yau, ita ce kawai fasahar bugu da za ta iya haifar da haske, rashin launi na karfe akan takarda, filastik, kwali da sauran wuraren bugawa.

Lokacin aikawa: Fabrairu-07-2023